TPS-PPS [Polyphenyline Sulfide]

Product lineup :

PPS(NC)-SC : Unfilled type

PPS(G40NC),(G40BK) : GK reinforced type

Features :

- PPs is a crystalline resin with very high thermal resistance.

- Low linear expansion coefficient and low water absorption result in high dimensional stability.

- Excellent resistance against chemicals.

- Continuous use temperature is high at 220ºC, but relatively low glass temperature of 90ºC means that care must be taken regarding use under high-load, high-temperature conditions.

- Good machinability like other super engineering plastics such as PAI, PEEK and PTFE for cutting. Unlike conventional PPS which can break easily while being worked, TPS-PPS(NC)-SC is produced using a original annealing method that reflects our long experience and advanced know-how in the field. This reduces internal stresses (residual distortion) during extrusion molding to an absolute mininum. When cut with well maintained carbide tools, a very clean finish can be obtained.

- Good suitability for welding like PTFE and PEEK, but compared to PVC and similar materials, the welding process requires a high level of skill and experience.

Use applicaiton :

Eletrical and electronic components, electrical household appliance parts, automotive parts, mechanical parts for chemical pumps, and semiconductor and LCD manufacturing equipment parts.

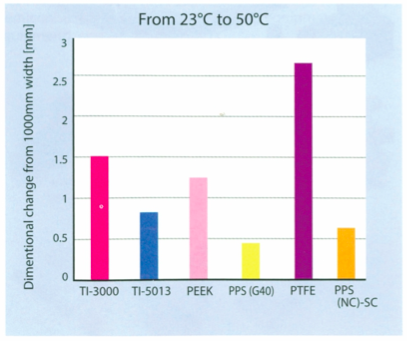

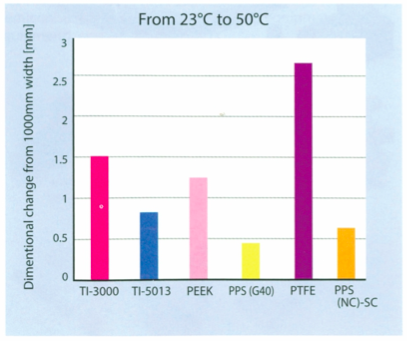

Excellent dimensional stability :

TPS-PPS(NC)-SC has excellent dimensional stability. The graph below plots the dimensional change when the usage environment temperature changes from room temperature (23ºC) to 50ºC. The values are calculated using the linear expansion coefficient.

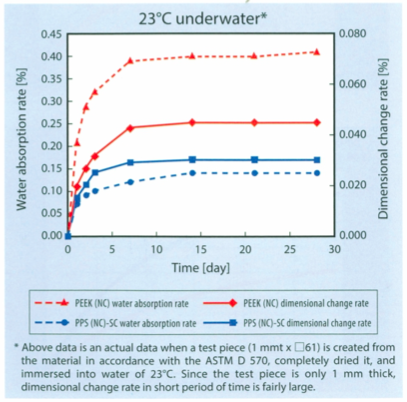

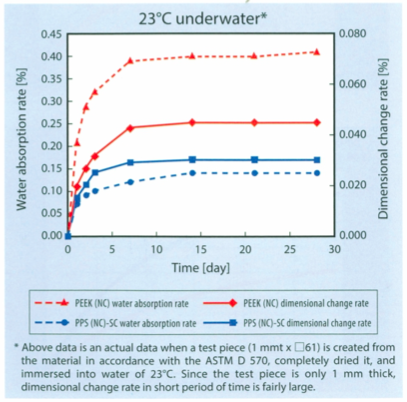

Excellent water absorption characteristics :

TPS-PPS(NC)-SC is a super engineering plastic material with extremely small dimensional change due to low water absortption.

PPS(NC)-SC : Unfilled type

PPS(G40NC),(G40BK) : GK reinforced type

Features :

- PPs is a crystalline resin with very high thermal resistance.

- Low linear expansion coefficient and low water absorption result in high dimensional stability.

- Excellent resistance against chemicals.

- Continuous use temperature is high at 220ºC, but relatively low glass temperature of 90ºC means that care must be taken regarding use under high-load, high-temperature conditions.

- Good machinability like other super engineering plastics such as PAI, PEEK and PTFE for cutting. Unlike conventional PPS which can break easily while being worked, TPS-PPS(NC)-SC is produced using a original annealing method that reflects our long experience and advanced know-how in the field. This reduces internal stresses (residual distortion) during extrusion molding to an absolute mininum. When cut with well maintained carbide tools, a very clean finish can be obtained.

- Good suitability for welding like PTFE and PEEK, but compared to PVC and similar materials, the welding process requires a high level of skill and experience.

Use applicaiton :

Eletrical and electronic components, electrical household appliance parts, automotive parts, mechanical parts for chemical pumps, and semiconductor and LCD manufacturing equipment parts.

Excellent dimensional stability :

TPS-PPS(NC)-SC has excellent dimensional stability. The graph below plots the dimensional change when the usage environment temperature changes from room temperature (23ºC) to 50ºC. The values are calculated using the linear expansion coefficient.

Excellent water absorption characteristics :

TPS-PPS(NC)-SC is a super engineering plastic material with extremely small dimensional change due to low water absortption.

Feb 22,2024